Historically, the steel industry has been the biggest consumer of natural graphite. However, with the new advances in battery technology and the need for a cleaner, greener source of energy to power the world, the graphite industry excepts much of it’s immediate future growth coming from the battery industry.

Below is a list of areas of application for graphite

Refractory

Graphite is one of the most common materials used in the production of functional refractories for the continuous casting of steel. In this application graphite flake is mixed with alumina and zirconia and then isostatically pressed to form components such as stopper rods, subentry nozzles and ladle shrouds used in both regulating flow of molten steel and protecting against oxidation

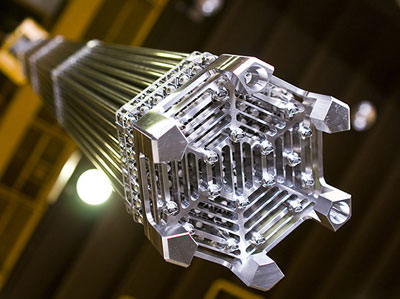

Nuclear Industry

High purity electrographite is used in large amounts for the production of moderator rods and reflector components in nuclear reactors. Their suitability arises from their low absorption of neutrons, high thermal conductivity and their high strength at temperature.

Batteries

Natural and synthetic graphite are used to construct the anode of all major battery technologies. The lithium-ion battery utilizes roughly twice the amount of graphite than lithium carbonate. The demand for batteries, primarily nickel-metal-hydride and lithium-ion batteries, has caused a growth in graphite demand in the late 1980s and early 1990s.

Steel Making

Natural graphite in this end use mostly goes into carbon raising in molten steel, although it can be used to lubricate the dies used to extrude hot steel. A carbon raiser is added to increase the carbon content of the steel to the specified level.

Brake Lining

Natural amorphous and fine flake graphite are used in brake linings or brake shoes for heavier (nonautomotive) vehicles, and became important with the need to substitute forasbestos. This use has been important for quite some time, but nonasbestos organic (NAO) compositions are beginning to cost graphite market share. A brake-lining industry shake-out with some plant closures has not helped either, nor has an indifferent automotive market. According to the USGS, US natural graphite consumption in brake linings was 6,510 tonnes in 2005.

Pencils

Pencil lead is most commonly a mix of powdered graphite and clay. It is chemically unrelated to the metal lead, whose ores had a similar appearance, hence the continuation of the name. Plumbago is another older term for natural graphite used for drawing, typically as a lump of the mineral without a wood casing.

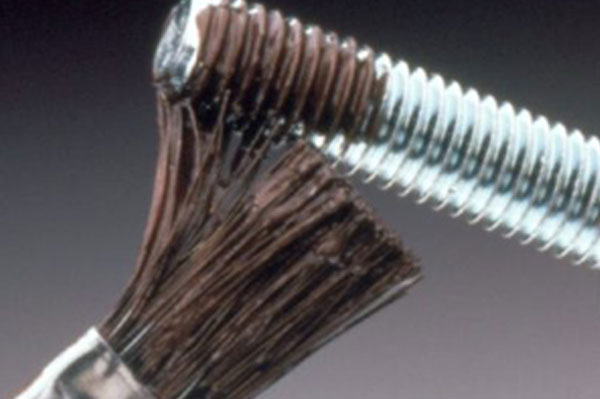

Lubricants

Graphite, due to its microstructure composed of hexagonal planes of hybridized sp2-sp3 carbon-carbon bonds, has very good lubricating properties. The single flakes are very thin and can easily position themselves between two surfaces in reciprocal motion generating a situation of three-body wear (surface-graphite-surface) with very low coefficients of friction.

Fire Retardants

Expandable Graphite Flake is now being used in a growing number of applications as an intumescent fire retardant additive, as an expansive agent and as a smoke suppressant. Most intumescent putties, caulks and firestop systems now rely on expandable graphite to provide the expansive force necessary to close off gaps and hales during the course of a fire.

Future demand is being driven by green technologies including Li-ion Batteries, Fuel Cells, Electronics, Construction Materials, Nuclear, and the Graphene revolution. Graphene, which occurs naturally in graphite, has unique physical properties and is among the strongest substances known. However, the process of separating it from graphite will require more technological development if it is meant to be used in everyday life. The rise and rise of the electric car is boosting the graphite industry and sparking incredible rises in the share prices of companies in Australia's fledgling sector. Traditionally used in refractories, steel making and ''lead'' pencils, graphite is now riding the wave of the electric car. With more electric cars getting built, demand for graphite, a key material in the lithium-ion batteries that power them, is also surging. Even American muscle icon Harley-Davidson has announced that it is building an electric motorbike. The reason why flake graphite has got into the mindset of the market is because it's the biggest bit of the lithium-ion battery. ''The market for lithium-ion batteries has really exploded to capture the imagination of investors.'' ''Lithium is a very volatile material and it can explode. Cars and aeroplanes have exploded,''